- Panvel Navi Mumbai

410206 MH India - +91 9321441804

[email protected]

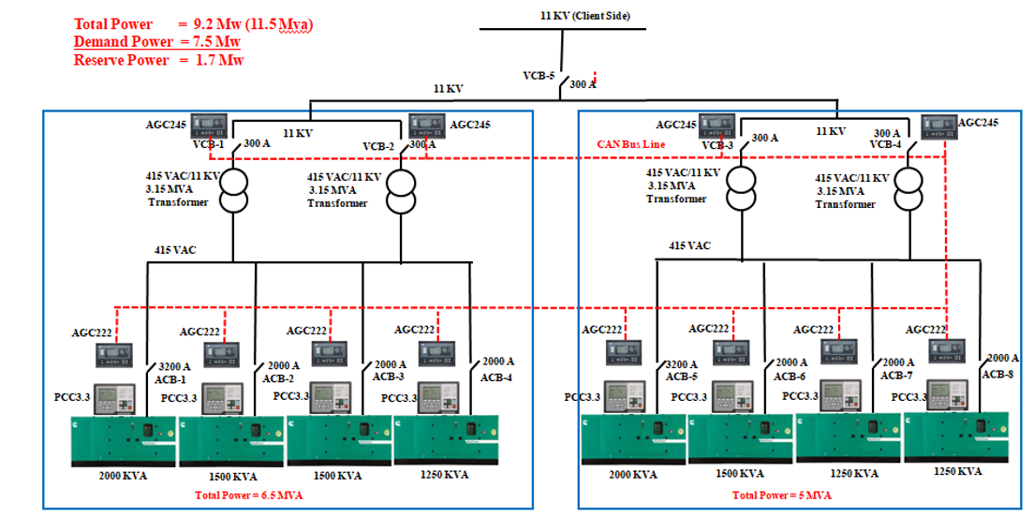

We collaborated with a Hiring Company in Mumbai to implement a DG and Multi-Grid paralleling solution for a Cement plant facing significant operational challenges. Due to the nature of cement manufacturing, the plant operates with high-power equipment, resulting in substantial energy demands.

The customer was experiencing unstable grid supply, leading to major production losses. To mitigate this issue, the Hiring Company recommended running DG sets in parallel with the grid continuously, ensuring uninterrupted operations and preventing further losses.

The customer agreed to deploy hired DG sets alongside the grid. We designed a robust solution based on the existing Single Line Diagram (SLD) of the plant, ensuring efficiency and reliability. The successful installation and commissioning of the system resulted in enhanced productivity and stable power supply. Both the Hiring Company and the customer expressed high satisfaction with the solution, as it enabled seamless operations without interruptions or additional financial burdens.This project underscores our commitment to delivering reliable power management solutions, optimizing performance for industrial applications.

Our esteemed customer in Nagpur was facing challenges with Maximum Demand (MD) management. When the MD exceeded the allowable limit, they had to either trip the load to maintain compliance or pay additional charges to Grid company for exceeding the MD threshold.

To address this issue, we recommended 500 kVA DG sets in parallel with the grid before MD exceeded. The customer accepted our proposal and opted for a comprehensive package, including a 500 kVA DG set and Synchronization Panel from us.

We successfully supplied, installed, and commissioned the system, ensuring seamless operation.

The customer is now highly satisfied, as the system allows them to run their plant without interruptions to their load while avoiding excess charges from the Grid Company.

This solution has not only improved operational efficiency but also provided cost savings and reliability, reinforcing our commitment to delivering effective power management solutions.

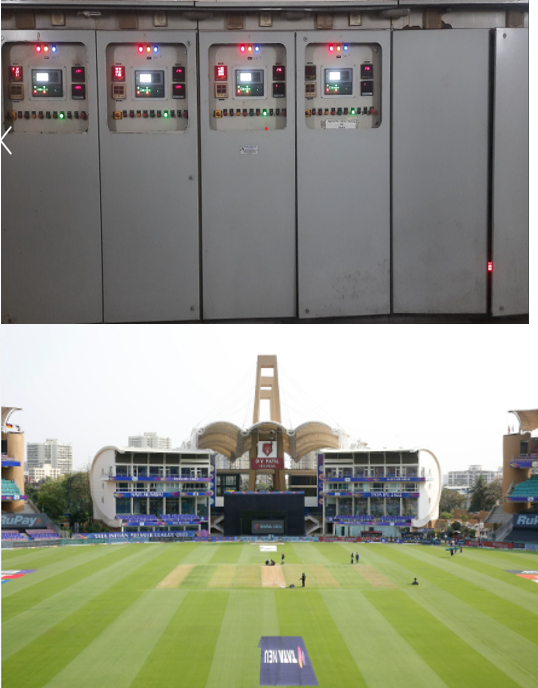

DY Patil Stadium, one of the largest cricket venues in Navi Mumbai, relies on four 500 kVA Caterpillar gensets, synchronized to provide uninterrupted power during match events.

However, the customer encountered challenges with genset synchronization during live matches, impacting reliability.

In 2022, following the COVID-19 pandemic, the stadium secured the IPL match event contract, with all matches scheduled to be played on a single ground due to ongoing pandemic concerns.

To ensure a seamless and reliable power supply, we took the strategic decision to retrofit the existing synchronization system using advanced DEIF Synchronization Controllers.

Our solution successfully enhanced system reliability, ensuring uninterrupted power delivery during high-profile events and reinforcing the stadium's ability to host large-scale matches without disruptions.

This case highlights our expertise in power management solutions, demonstrating our commitment to delivering efficient and robust synchronization systems for critical applications.

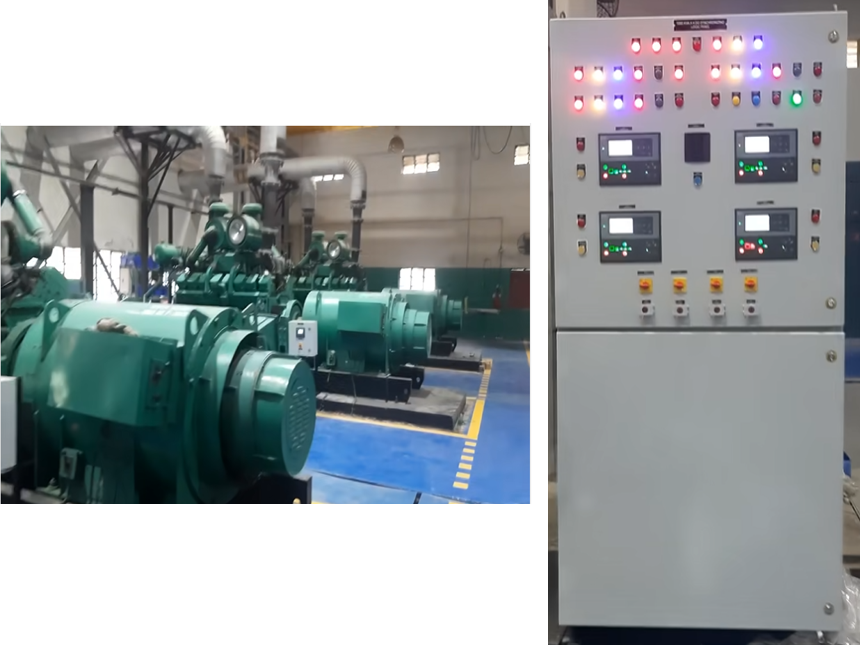

A leading Genset manufacturing company in Mumbai required a logic panel to synchronize and ensure the continuous operation of 2MW MAN DG sets with a single grid, transitioning from a multi-grid setup.

The key challenge was Grid switching via a single selector switch, while seamlessly integrating CT, PT, and other feedback mechanisms from multiple grids.

Addressing this complexity, we designed a customized logic panel, allowing the operator to control the grid supply from the DG-Grid Synchronization Panel while ensuring all essential safety measures during the parallel operation of the grid.

This innovative solution not only streamlined grid switching but also enhanced operational efficiency and reliability, ensuring uninterrupted power supply.

The Data Centre in Mumbai was experiencing challenges with DG operation during power failures. The facility operated with three Cummins 910 kVA DG sets, running as per demand. However, during a power failure, operators had to manually start the DG sets to supply power to the data center. In the event of a DG tripping, manually switching to another DG set was time-consuming and operationally challenging.

To resolve this issue, we provided the customer with a "DG AMF Logic Panel", designed to automate genset priority selection. With this system:

This solution significantly enhanced reliability and efficiency, ensuring uninterrupted operations and eliminating downtime risks.

An event management company sought our support to synchronize 4 Nos Cummins and CAT DG sets for uninterrupted power supply at a major music event in Mumbai.

The customer already had a synchronization panel for two Cummins DG sets but required an additional panel to synchronize all four DG sets seamlessly.

We provided a unique design solution that allowed flexible operation, enabling the panel to support both single DG set and multiple DG set synchronization as needed.

Our team successfully supplied individual synchronization panels, featuring a custom-designed Busbar Canopy, ensuring efficient power distribution and seamless integration.

The solution delivered enhanced reliability and adaptability, meeting the customer's requirements while ensuring consistent power supply throughout the event.

A capsules manufacturing plant was experiencing frequent Grid supply interruptions, resulting in significant production losses due to continuous power disruptions.

To mitigate this issue, we recommended that the customer parallel their Cummins 4 Nos 1500kVA DG sets with the Multi Grid, ensuring uninterrupted operations during power restoration.

Additionally, we advised them to establish an agreement with the Grid company, requesting prior notification before any scheduled power cut-offs. This would allow them to seamlessly transition the load to the DG sets by synchronizing with the grid, eliminating downtime and ensuring uninterrupted production.

This proactive approach has enhanced operational reliability, minimizing disruptions and optimizing efficiency for the customer.

We’re proud to share the successful completion of a highly challenging project for the Government of India at the 512 Army Base Workshop, Pune The workshop had a 4x1000 kVA Cummins genset installed in the 1980s, which remained unsynchronized until 2021 leading to operational challenges—especially in managing sudden load demands during power failures. Despite efforts from several industry experts, synchronizing the aged genset proved unsuccessful. Most companies recommended replacing the unit entirely—an option that wasn’t feasible for the 512 team.

Post the COVID-19 pandemic, we were invited by a key industry player to assess the situation. With confidence in our expertise and commitment, we visited the site, understood the challenges, and were entrusted with the project.

We’re delighted to share that we not only secured the order but also successfully executed the synchronization by using DEIF AGC150 advanced Synch Controller and SGC120 as a genset controller —bringing a decades-old system into active alignment.

Formerly known as Coastal Gujarat Power Limited (CGPL), Tata Power generates 4,000 MW of TG power, supplying it to the National Grid in India.

To ensure continuous operations, they utilize an auxiliary power plant powered by DG sets, which support TG auxiliaries in the event of a TG trip. Once the TG is restored, the DG sets resynchronize with TG power, preventing load interruptions.

A few years ago, a Mumbai-based company provided Tata Power with a DG-Grid Synchronization Panel, incorporating an older synchronization system to meet operational requirements.

Recently, we upgraded the panel with the DEIF AGC 4 Advanced Synchronization & Power Management Control System, significantly enhancing reliability and efficiency in power transition and load stability.

This modernization ensures seamless DG-TG synchronization, optimizing power continuity and operational performance.